Products

Subsea Pumps

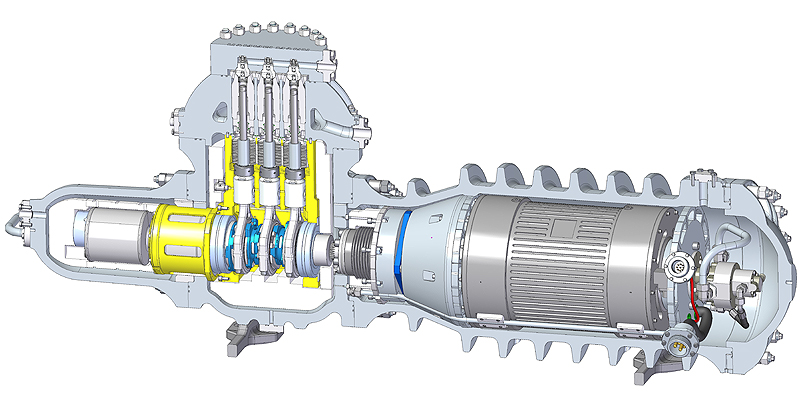

OHI has worked directly with Hammelmann®Corp to provide a capable subsea chemical pump that is characterized as a marinized version of either the Hammelmann® HDP70, or HPD20 series pumps. This pump is rated for submersion in sea water to depths of 10,000ft (3050m) and applications where the working fluid is required to be injected at pressures up to 20,000psi (1380bar) These pumps use field proven technologies for pumping nearly all chemicals used for subsea well dosing. Fluids are typically Methanol, LDHI, Wax, Scale, and Corrosion Inhibitors. Hammelmann® pumps are capable of pumping these and many other fluids.

The technology and configuration of the pump is a triplex three plunger design, labyrinth metal to metal sealing sleeve, no packings, packaged with either a fixed or variable displacement crankshaft. In the variable displacement version, the pump utilizes a servo-motor to actuate the crankshaft cam system allowing a minimum 20:1 turn down ratio. The servo motor is extremely accurate and precise, and is used to adjust flow rate for low dose chemicals and for use with chemical metering valves.

Subsea Chemical Storage Tank

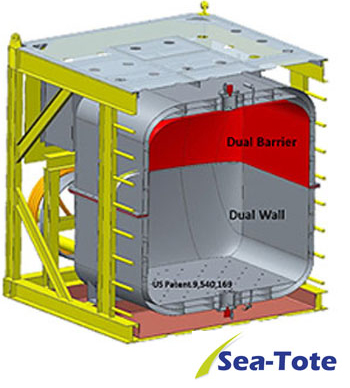

The OHI subsea chemical storage tank (Sea-Tote) is ideally suited for storage of well dosing chemicals and designed to work seamlessly with OHI's subsea chemical systems. The subsea storage system is available in multiple sizes

while at this time is anticipated that 100, 200, and 300 (16m3, 32m3, 32m3) barrel storage designs meet most all general needs. Key to the design of the tank are three critical safety systems incorporating dual barriers between the chemicals and the subsea environment. The tank structure is a dual stainless steel shell, with compensating fluid in the void between the inner and outer shell. A barrier of

flexible chemical resistant fabric

separates the chemicals from compensating sea water, also incorporates dual layers. Around the perimeter and separation of the tank halves there is a dual seal. In all three of these features, and patented OHI test system

is included that can test each of these critical safety features on-shore, during installation, and at any time while in operation subsea. US Patent 9,540,169.

The OHI subsea chemical storage tank (Sea-Tote) is ideally suited for storage of well dosing chemicals and designed to work seamlessly with OHI's subsea chemical systems. The subsea storage system is available in multiple sizes

while at this time is anticipated that 100, 200, and 300 (16m3, 32m3, 32m3) barrel storage designs meet most all general needs. Key to the design of the tank are three critical safety systems incorporating dual barriers between the chemicals and the subsea environment. The tank structure is a dual stainless steel shell, with compensating fluid in the void between the inner and outer shell. A barrier of

flexible chemical resistant fabric

separates the chemicals from compensating sea water, also incorporates dual layers. Around the perimeter and separation of the tank halves there is a dual seal. In all three of these features, and patented OHI test system

is included that can test each of these critical safety features on-shore, during installation, and at any time while in operation subsea. US Patent 9,540,169.

SCIU-Subsea Chemical Injection Unit

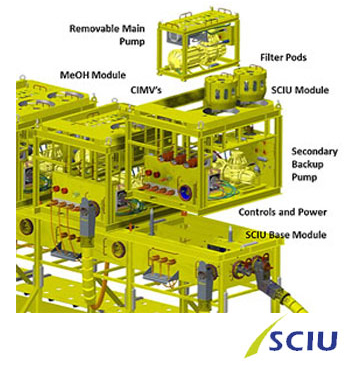

OHI is a leader in the development of an integrated subsea chemical injection package. OHI calls this the Subsea Chemical Injection Unit, or SCIU. This is characterized as a subsea chemical injection package that includes the chemical pump, motor control, instrumentation, filtration, anti-backflow system, and both the hydraulic connections for low pressure inlet and high pressure outlet for the system. OHI's leadership includes detailed effort and analysis for both optimal performance, and users operational interfaces. Optimal performance is achieved by using field proven equipment and accessories, and intuitive design for long life and low maintenance. User interfaces include such key features as A/B redundant systems with multiple levels of retrievability, ease of service, and most important, modularity for optimal or reconfiguration.

OHI is a leader in the development of an integrated subsea chemical injection package. OHI calls this the Subsea Chemical Injection Unit, or SCIU. This is characterized as a subsea chemical injection package that includes the chemical pump, motor control, instrumentation, filtration, anti-backflow system, and both the hydraulic connections for low pressure inlet and high pressure outlet for the system. OHI's leadership includes detailed effort and analysis for both optimal performance, and users operational interfaces. Optimal performance is achieved by using field proven equipment and accessories, and intuitive design for long life and low maintenance. User interfaces include such key features as A/B redundant systems with multiple levels of retrievability, ease of service, and most important, modularity for optimal or reconfiguration.

Hammelmann® Process Pumps

OHI provides representation, engineering support, and specification for Hammelmann's® wide range of process pumping systems. Call on OHI to assist in specific application inquiries, and for integration support of these high quality systems into your factory application or for inclusion in your offshore facilities.

OHI provides representation, engineering support, and specification for Hammelmann's® wide range of process pumping systems. Call on OHI to assist in specific application inquiries, and for integration support of these high quality systems into your factory application or for inclusion in your offshore facilities.

Hammelmann® products are manufactured in Oelde, Germany and in their US Dayton Ohio plant. Parts, factory service and repair for the Gulf of Mexico is provided by Hammelmann's® LaPorte Texas operation.

Umbilical Termination and Manifolds

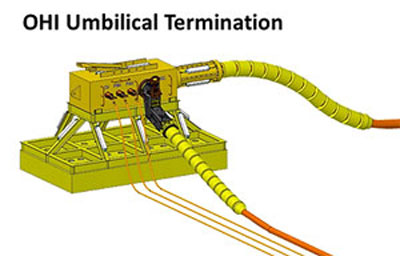

OHI can custom engineer and build umbilical terminations and manifolds to support field developments incorporating the subsea chemical injection pumps and tanks concepts. In these latest configurations, the umbilical terminations can be greatly simplified due to the removal of much of the hydraulic tubing. In a multi-well field development, the pumping system SCIU can be placed on a manifold base and connected utilizing conventional field proven hydraulic and electrical/fiber optic remotely operated vehicle ROV flying leads and operation standards.

OHI can custom engineer and build umbilical terminations and manifolds to support field developments incorporating the subsea chemical injection pumps and tanks concepts. In these latest configurations, the umbilical terminations can be greatly simplified due to the removal of much of the hydraulic tubing. In a multi-well field development, the pumping system SCIU can be placed on a manifold base and connected utilizing conventional field proven hydraulic and electrical/fiber optic remotely operated vehicle ROV flying leads and operation standards.

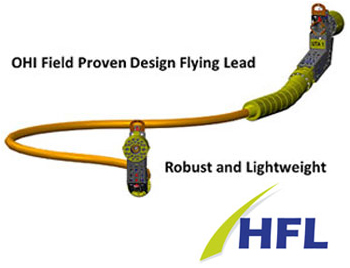

Hydraulic Flying Leads

OHI has developed an innovative Hydraulic Flying Lead (HFL) that combines both field proven technology while incorporating updates in materials and tubing termination technology greatly reducing the weight and ROV installation operability. In field developments using the latest SCIU chemical injection designs, the HFL from the SCIU manifold to the tree is configured nearly the same as conventional systems so operators of these fields can take advantage of this new lightweight design to reduce cost and increase operability.

OHI has developed an innovative Hydraulic Flying Lead (HFL) that combines both field proven technology while incorporating updates in materials and tubing termination technology greatly reducing the weight and ROV installation operability. In field developments using the latest SCIU chemical injection designs, the HFL from the SCIU manifold to the tree is configured nearly the same as conventional systems so operators of these fields can take advantage of this new lightweight design to reduce cost and increase operability.

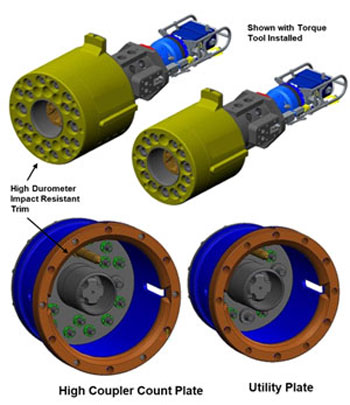

Junction and Stab Plates

OHI's hydraulic stab plates utilize a field proven and recognized docking and latching mechanism. The system is adaptable to all three well known industry accepted hydraulic coupling suppliers. These API standard stab plates are designed for deep water "free-fly" HFL ROV installation.

OHI's hydraulic stab plates utilize a field proven and recognized docking and latching mechanism. The system is adaptable to all three well known industry accepted hydraulic coupling suppliers. These API standard stab plates are designed for deep water "free-fly" HFL ROV installation.